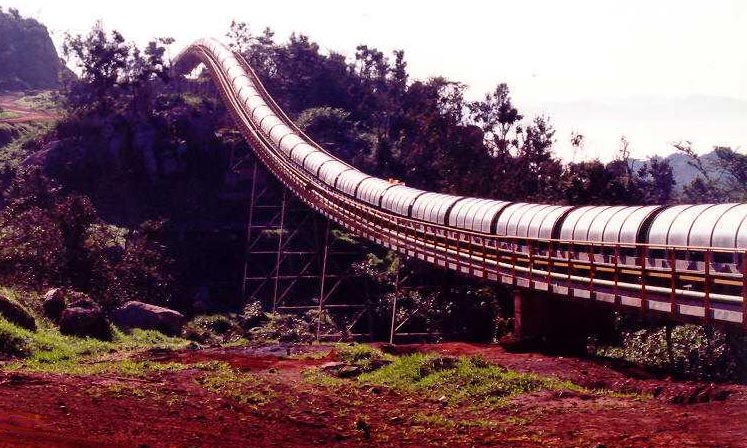

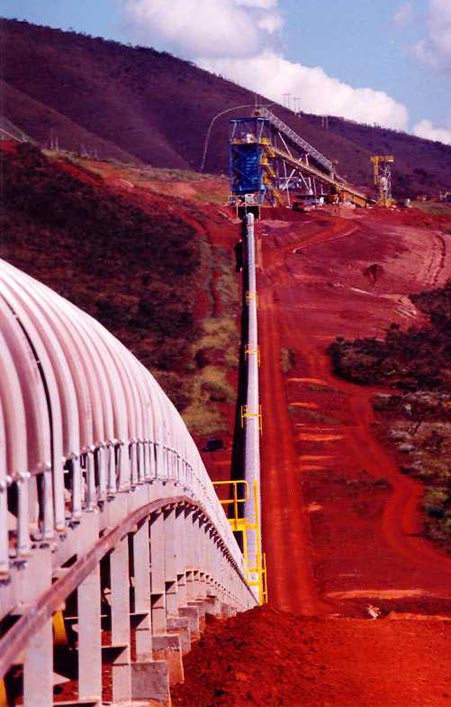

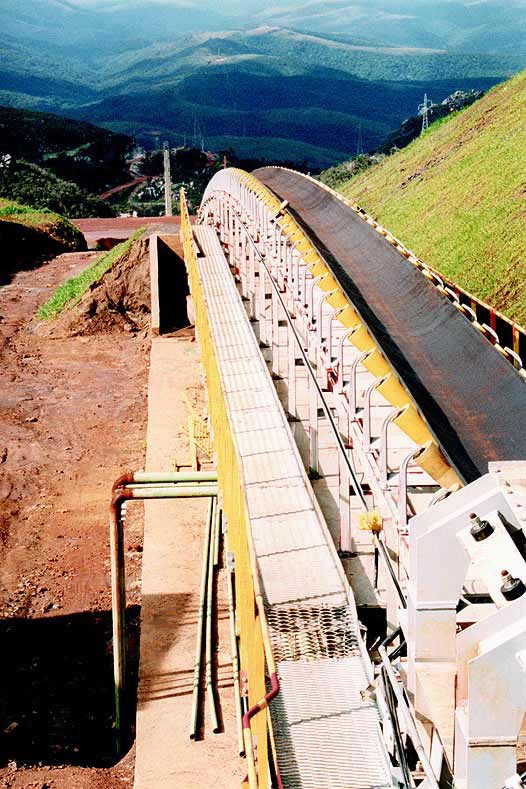

Pico Project

Pico Project Design services included mechanical design, dynamic analysis, brake system design, instrumentation, and control system design. The control system design included the logic development, programming (Allen Bradley PLC5/30), on-site commissioning, and performance testing. The control system included a supervisory system (FactoryLink) provided by others.

| The project is a 4.7 Km route at 3000TPH for the transportation of iron ore consisting of one overland, three downhill, six plant conveyors and an automated trainload out system. It also included two silo / feeder systems, a shuttle conveyor (moveable head) and interfacing to the stacker / reclaimer systems. |

Previous

Next

Año de construcción: 1994

Ubicación: Pico, MBR, Brazil

Length : 4.73 km

Potencia: 2,800 kW

Tonelaje: 3,000 tph

Tension: ST-1600 and ST-2000 N/mm

Velocidad: 4.6 m/s

Material: Iron Ore

Interesting Features:

- DC drives on downhill and overland conveyors.

- Fluid couplings on plant conveyors.

- Fully automated train loading system.