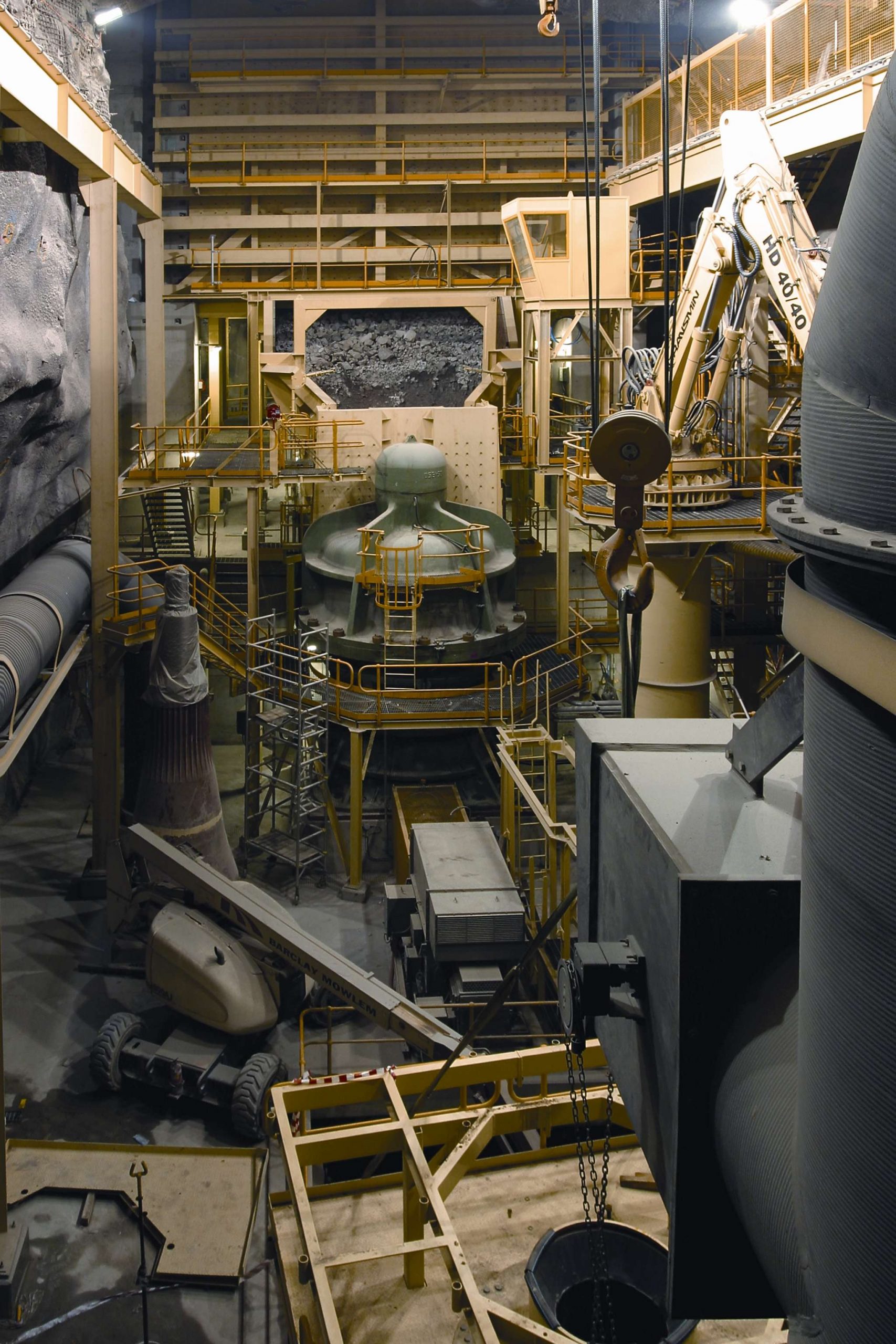

Northparkes Lift2 UG Project

The Northparkes Mine underground Lift 2 conveyor system included mechanical design of three (3) conveyors CV010, CV011 and CV012 conveying primary crushed copper ore from the new Lift 2 block cave underground crusher station located 900 meters underground to the existing underground skip hoist system over 2.8km distance with an overall conveyor lift of 470 meters.

Conveyor CV-010

Año de construcción: 2004

Ubicación: New South Wales, Australia

Length : 1.005 km

Potencia: 2,238 kW

Tonelaje: 1,050 tph design / 900 tph nominal

Tension: ST-2250 N/mm

Velocidad: 3.0 m/s

Material: Crushed Copper Ore

Conveyor CV-011

Año de construcción: 2004

Location: New South Wales, Australia

Length : 0.25 km

Potencia: 30 kW

Tonelaje: 1,050 tph design / 900 tph nominal

Tension: 6PN-150 N/mm

Velocidad: 1.5 m/s

Material: Crushed Copper Ore

Conveyor CV-012

Año de construcción: 2004

Location: New South Wales, Australia

Length : 1.73 km

Potencia: 1,275 kW

Tonelaje: 1,050 tph design / 900 tph nominal

Tension: ST-3200 N/mm

Velocidad: 3.0 m/s

Material: Crushed Copper Ore

Interesting Features:

- Suspended conveyor modules hung from the drift tunnel roof/back.

- Conveyor CV010 incorporated a horizontal curve at the head end to compensate for poor geological conditions found during construction.

- Conveyor lift of 470 meters.

- Flywheels on each conveyor to extend and match drift stop times.

- Conveyor CV-010 has 900 meter Convex Curve and a 2,100 meter Horizontal Curve.