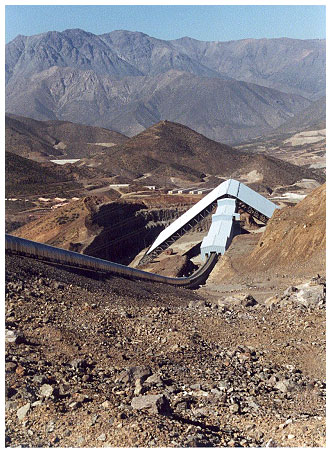

Los Pelambres Project – World Record

Los Pelambres Project services included mechanical design, dynamic analysis, brake system design, splice and pulley FEA, curved chute design, belt flap study, instrumentation, and control system design. The control system design included the logic development for Siemens S5-155H PLC with hot backup, supervisory system (Siemens WinCC) development and programming, on-site commissioning in collaboration with Siemens and performance testing.

| The project is a 12.7 Km tunnel conveyor at 9900 TPH for the transportation of coarse copper ore. The route consists of three downhill flights with a total drop of 1.3 Km. One conveyor includes a multiple position moveable head and two conveyors have drive capacities of 10,000 kW. The total regenerative capacity is 25,000 kW. Other equipment includes four variable speed feeders. |

Año de construcción: 2000 & 2008(Capacity Upgrade)

Ubicación: Minera Los Pelambres, Chile

Length : 12.653 km

Potencia: 25,000 kW

Tonelaje: 9,900 tph

Tension: ST-7800 N/mm and ST-4000 N/mm

Velocidad: 6.8 m/s

Material: Copper Ore

Chute Design

Project scope included chute design and DEM analysis for three chutes in a system conveying copper ore up to 11,000 tph.

Number of Chutes: 3

Chute Design: Yes

ROCKY DEM Analysis: Yes

Tonelaje: 11,000 tph

Interesting Features:

- Automatic feeder selection and sequencing with closed loop tonnage control.

- Multi-speed conveyor operation.

- Drive control load sharing, with adding / dropping individual drives while the conveyor is in operation (done with PLC logic).

- Combined digital and proportional brake control.

- Stop control with three levels of drive control and five levels of brake control.

- Automatic shuttle position and stockpile level control.

- Supervisory system with hyperlinked advanced help.