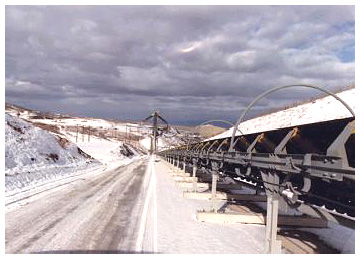

Bingham Project

Bingham Project – Provided the design criteria and mechanical specifications for all components for a 9 km overland system, as a consultant to Ralph M. Parsons Co. Provided the mechanical design support to PHB Wessehutte, including head-tail 6000 hp drive (4 x 1500 hp) wound rotor motor control / logic, and head-tail brake PLC logic code for the system of four large conveyors. Subsequent to commissioning, a PWH takeup pulley failed in the shell. CDI was not involved in the pulley design. CDI investigated the shell failure and determined the shell to be under-designed. Provided engineering audit of remaining pulleys, using CDI failure criteria, and found similar shell flaws on high tension assemblies. These pulleys failed within three months of our audit.

Año de construcción: 1988

Ubicación: Kennecott, Bingham Canyon Mine, Utah, USA

Length : 10.44 km

Potencia: 16,800 kW

Tonelaje: 10,000 tph

Tension: ST-3000 N/mm

Velocidad: 4.7 m/s

Material: Coal

Interesting Features:

- Longest high tonnage overland in USA @ 10,000 STPH